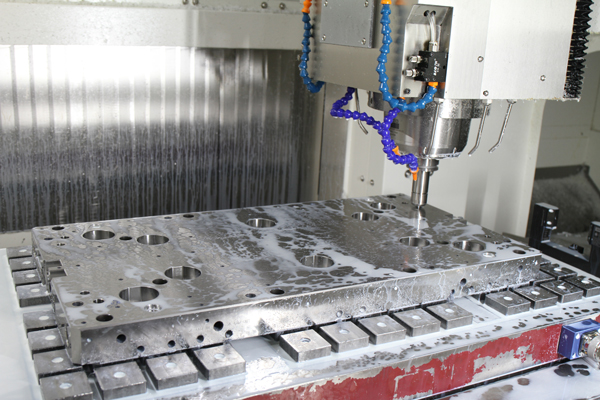

In the field of mold CNC machining, cutting speed is of utmost importance as it pertains to the amount of material removed by a rotating milling cutter and plays a decisive role in shaping the form of the molded part. However, in actual machining processes, numerous factors directly or indirectly influence the machining speed of the cutting tools in mold CNC machining. The following is a detailed elaboration from multiple aspects.

Material Properties as the Fundamental Influencing Factor

The properties of the material to be machined are one of the key factors affecting the cutting speed. Generally, there is a close relationship between the softness or hardness of the material and the machining speed. In most cases, the softer the material to be processed, the higher the speed that can be set for the machine. This is because when cutting softer materials, the resistance encountered by the cutting tool is relatively small, allowing the tool to cut into the material more smoothly and thus achieve a faster cutting speed. For example, when machining relatively soft aluminum alloys, the cutting speed can be set relatively high; whereas when processing harder stainless steels, the cutting speed needs to be appropriately reduced to prevent excessive tool wear or damage.

Tool Selection Determines Machining Efficiency

The selection of cutting tools holds a pivotal position in mold CNC machining. Different types of tools vary significantly in terms of material and performance, which in turn affects the cutting speed. Some tools are made of relatively basic high-speed steel (HSS), which has relatively limited hardness and durability. Others are manufactured using tungsten carbide (tungsten carbide or solid carbide), which offers higher hardness and wear resistance. Additionally, some tools are coated with special layers, greatly enhancing their hardness and durability. These coated tools can even process very hard materials, such as steel, by optimizing the cooling conditions. Choosing the right tool can fully leverage its performance advantages, improving both the cutting speed and machining quality.

Machining Type Influences Speed Setting

The type of machining is also an important factor influencing the cutting speed. Different machining activities, such as rough machining, finish machining, turning, and thread machining, have varying requirements for the cutting speed. During rough machining, the main objective is to quickly remove a large amount of material, so the cutting speed can be appropriately increased to improve machining efficiency. In contrast, finish machining places more emphasis on the surface quality and dimensional accuracy of the part, and the cutting speed is usually relatively lower to ensure machining stability and accuracy. Specific machining methods like turning and thread machining also require adjustments to the cutting speed according to specific process requirements.

Hole Depth and Material Quantity Are Related

There is a certain relationship between hole depth and the amount of material, and this relationship affects the cutting speed. Generally, the larger the amount of material, which implies more material needs to be removed, the cutting speed can be appropriately increased within the capabilities of the tool and the machine to shorten the machining time. However, it should be noted that when the hole depth is too great, the resistance and vibration encountered by the tool during cutting will increase, which may affect the machining quality and tool life. In such cases, it is necessary to comprehensively consider the cutting speed and other machining parameters.

Workpiece Shape and Clamping Force Affect Rigidity

The shape of the workpiece and its accessories, as well as the clamping force of the cutting tool, also have a non-negligible impact on the cutting speed. The rigidity of tool installation and the tightness of the workpiece (considering the shape that may cause deformation) directly affect the stability and vibration during the cutting process. If the tool is not installed firmly enough or the workpiece is prone to deformation during machining, the cutting speed needs to be appropriately reduced to avoid a significant decline in machining quality or tool damage due to excessive vibration. Therefore, before machining, it is essential to ensure proper tool installation, appropriate clamping force, and reasonable clamping and fixation of the workpiece.

Lubricants Help Increase Speed

Lubricants play a crucial role in mold CNC machining, and sufficient lubrication can significantly improve the cutting speed. During the cutting process, a large amount of heat and friction are generated between the cutting tool and the material. This not only accelerates tool wear but also affects the machining quality and cutting speed. Lubricants can form a lubricating film between the tool and the material, reducing friction and heat generation, minimizing tool wear, and thus improving the cutting speed and machining efficiency. At the same time, good lubrication can also improve the quality of the machined surface, reducing the occurrence of burrs and scratches.

Machine Type Determines Load-Bearing Capacity

Different types of machines vary in performance and structure, which determines their different abilities to withstand cutting speeds. Compared with lighter machines, sturdier machines generally have greater rigidity and stability and can withstand higher cutting speeds and cutting forces. This is because sturdy machines are designed and manufactured using higher-quality materials and more reasonable structures, enabling them to better resist vibration and deformation during the cutting process, thereby ensuring machining stability and accuracy. Therefore, when selecting a machining machine, it is necessary to choose an appropriate machine type according to specific machining requirements and material characteristics to fully leverage its performance advantages.

In mold CNC machining, the cutting speed is influenced by a combination of multiple factors. In actual machining processes, it is necessary to comprehensively consider these factors and reasonably adjust the cutting parameters to achieve efficient and high-quality mold machining.