In the manufacturing industry, injection molding is a widely used processing technique for producing various plastic products, ranging from daily necessities to precision electronic components. As the core tool for injection molding, the design quality of injection molds directly impacts product quality, production efficiency, and costs. Standardization plays a pivotal role in injection mold design. It not only helps improve the efficiency and quality of mold design but also brings significant economic benefits and competitive advantages to enterprises.

Standardization Enhances Design Efficiency

Modular Design

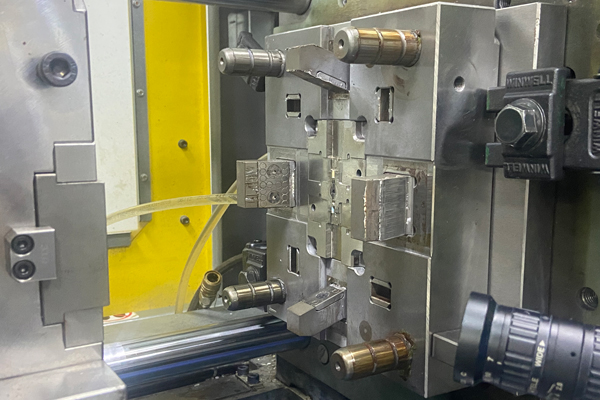

Standardization in injection mold design involves establishing a set of universal design modules and a standard parts library. For example, common mold structures such as two-plate molds and three-plate molds, as well as standard parts like guide posts, guide bushings, ejector pins, and lifters, all have unified design specifications and dimensional standards. When designers are working on mold design, they can directly select appropriate modules and parts from the standard parts library without having to redesign and draw them each time. This is similar to building with building blocks, where different standard modules are combined to quickly construct a mold structure that meets product requirements. This modular design approach significantly shortens the design cycle and improves design efficiency. For instance, designing a simple plastic housing mold using standardized design may only take a few days, while traditional design methods may require several weeks or even longer.

Reducing Repetitive Work

In a non-standardized design environment, each designer may have their own design habits and methods. For the same or similar product molds, different design solutions and structures may emerge. This not only increases communication costs and coordination difficulties during the design process but also easily leads to repetitive work. Standardized design requires designers to follow unified design specifications and procedures. For similar product molds, the same or similar design solutions and structures can be adopted. This avoids unnecessary repetitive design work, allowing designers to devote more time and energy to innovative design and solving key technical problems.

Ensuring Mold Quality

Unified Design Standards

Standardization in injection mold design establishes unified design standards and technical requirements, covering aspects such as mold dimensional accuracy, surface roughness, material selection, and heat treatment processes. Designers must strictly adhere to these standards during the design process to ensure that the mold quality meets the requirements. For example, regarding the dimensional accuracy of the mold cavity and core, standardization specifies strict tolerance ranges. Designers must ensure that the product’s dimensional accuracy falls within this range to guarantee stable dimensions and reliable quality of the produced plastic products. Unified design standards also prevent design quality issues caused by differences in designers’ individual skill levels, improving the overall quality level of molds.

Optimizing Mold Structure

During the standardized design process, a large number of mold design cases are summarized and analyzed to extract the optimal mold structures and design solutions. These optimized structures, which have been verified through practice, are incorporated into the standardized design specifications for designers’ reference and application. For example, for common plastic products such as bottle caps and plastic boxes, standardized design has formed mature structural solutions, including gate location, runner design, and ejection methods. By adopting these optimized structures, designers can reduce the number of mold trials, improve the molding quality and production efficiency of the mold. At the same time, the optimized mold structures also have better strength and rigidity, extending the mold’s service life.

Reducing Production Costs

Lowering Mold Manufacturing Costs

Standardized design makes mold components universal and interchangeable. During mold manufacturing, standard parts can be produced through batch processing, improving production efficiency and reducing the manufacturing cost per part. For example, guide posts and guide bushings can be batch-processed using CNC machine tools and then undergo unified quality inspection and inventory management. When a new mold needs to be manufactured, appropriate standard parts can be directly selected from the inventory without the need for reprocessing, thus shortening the mold manufacturing cycle and reducing manufacturing costs. In addition, standardized design can also reduce the scrap rate and rework rate during mold manufacturing, further lowering production costs.

Reducing Mold Maintenance Costs

Since the components of standardized molds are universal and interchangeable, if a component is damaged or worn during mold use, standard parts of the same specification can be easily purchased from the market for replacement without the need for custom-made components. This not only shortens the mold repair time, reduces production losses caused by mold downtime, but also lowers mold maintenance costs. For example, in a certain enterprise, the ejector pin of an injection mold broke during use. Since the mold adopted standardized design, the enterprise quickly purchased an ejector pin of the same specification from the local mold parts market for replacement, and the mold soon resumed normal operation, avoiding long downtime due to waiting for custom-made components.

Promoting Collaborative Cooperation and Knowledge Inheritance

Facilitating Internal Collaborative Cooperation within Enterprises

In large enterprises, mold design often requires the joint participation of multiple departments and teams, such as the product design department, mold design department, and mold manufacturing department. Standardized design provides a unified language and specification for collaborative cooperation among various departments within the enterprise. Personnel from different departments can communicate and collaborate based on the same design standards and procedures, reducing misunderstandings and errors caused by inconsistent information. For example, when the product design department is designing a product, it can refer to the standardized requirements of mold design to ensure that the product’s structural design is feasible for mold manufacturing. The mold design department can closely cooperate with the mold manufacturing department during mold design and optimize the mold structure according to manufacturing process requirements to improve the mold’s manufacturability.

Benefiting Knowledge Inheritance and Technical Accumulation

Standardization in injection mold design is a summary and precipitation of an enterprise’s long-term design experience and technical achievements. By incorporating excellent design solutions, structures, and technical requirements into the standardized design specifications, an enterprise’s knowledge assets can be effectively protected and inherited. Newly hired designers can quickly master the basic methods and techniques of mold design by learning and following the standardized design specifications, reducing training time and costs. At the same time, standardized design can also promote technical exchanges and innovation within the enterprise. Designers can make improvements and innovations on the basis of standardized design, continuously improving the enterprise’s mold design level and technical competitiveness.

Adapting to Market Changes and International Demands

Quickly Responding to Market Demands

In today’s fiercely competitive market environment, the speed of product replacement is getting faster and faster, and enterprises need to be able to quickly launch new products to meet market demands. Standardized design can improve the flexibility and adaptability of mold design, enabling enterprises to quickly modify and adjust molds according to market demands. For example, when the market puts forward new requirements for the appearance or dimensions of a certain plastic product, designers can quickly produce a new mold that meets market demands by replacing some standard parts or making local modifications to the mold structure based on the original standardized mold, shortening the product’s time to market and improving the enterprise’s market competitiveness.

Complying with International Standards and Expanding International Markets

With the development of global economic integration, more and more enterprises are beginning to expand into international markets. In the international market, injection molds need to comply with international general standards and specifications, such as ISO standards and DIN standards. Standardization in injection mold design can make an enterprise’s mold design comply with international standard requirements, improving the mold’s universality and interchangeability and facilitating the circulation and trading of molds in the international market. At the same time, mold designs that comply with international standards can also enhance an enterprise’s international image and reputation, laying a solid foundation for the enterprise to expand into international markets.

Conclusion

Standardization in injection mold design is an inevitable trend in the development of the manufacturing industry. It is of great significance in improving design efficiency, ensuring mold quality, reducing production costs, promoting collaborative cooperation and knowledge inheritance, and adapting to market changes and international demands. Enterprises should attach great importance to the standardization of injection mold design, establish a sound standardized design system, strengthen training and management in standardized design, and continuously improve their mold design level and market competitiveness. Only in this way can enterprises remain invincible in fierce market competition and achieve sustainable development.