In the medical field, every millimeter of precision and every gram of material compatibility can be a matter of life or death. Injection molding technology, with its efficiency, precision, and customizability, has become an indispensable “behind-the-scenes hero” in medical device manufacturing. From implantable devices to laboratory consumables, from surgical instrument housings to drug delivery systems, injection molding is quietly but powerfully reshaping modern medical manufacturing standards.

I. Injection Molding: The “All-Rounder” in Medical Manufacturing

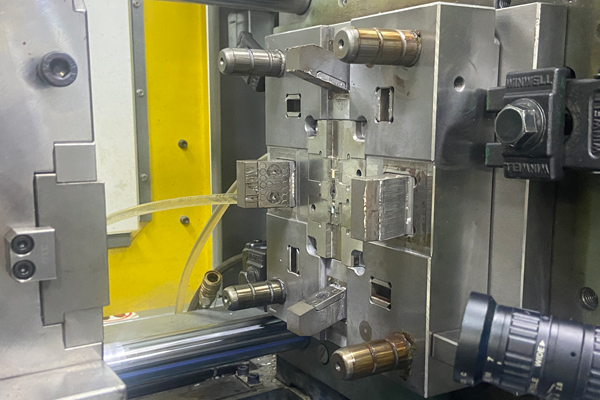

Injection molding is a process that involves injecting molten plastic under high pressure into a mold, where it cools and solidifies into precision parts. In the medical industry, its applications far exceed those of ordinary industrial products:

- Exclusive platform for medical-grade plastics: Materials like PP, PE, and PPSU, when processed via injection molding, meet stringent requirements for biocompatibility, chemical resistance, and high-temperature sterilization, making them suitable for direct human contact or implantation.

- From micro-components to large equipment: The technology can produce parts as small as 0.1mm (e.g., microfluidic chips) or as large as medical device housings, all with high consistency.

- Naturally compatible with regulatory compliance: The closed-loop production and full process controllability of injection molding align perfectly with the medical industry’s demands for cleanliness, traceability, and material safety.

II. Key Applications of Medical Injection Molding

Why do medical suppliers favor injection molding? The answer lies in the following scenarios:

1. Implantable Components: Micron-Level Precision to Safeguard Lives

Heart stents, orthopedic screws, and artificial joints must withstand long-term mechanical loads in the body. Injection molding ensures dimensional tolerances ≤0.005mm through micron-level mold control, while using high-performance materials like PEEK for a balance of strength and biocompatibility.

2. Laboratory and Diagnostic Consumables: Mass Production Without Compromising Quality

Beakers, test tubes, and PCR plates require properties like enzyme-free surfaces, pyrogen-free materials, and low-temperature transport resistance. Injection molding enables daily production of tens of thousands of units, reducing per-unit costs by over 60% through mold optimization (e.g., multi-cavity designs).

3. Surgical Instruments and Device Housings: Balancing Function and Aesthetics

Laparoscopic handles, ultrasonic knife housings, and other complex structural parts often integrate anti-slip textures, sealed interfaces, and wireless charging modules. Injection molding achieves “one-step molding with multiple functions” via techniques like insert molding and two-shot molding, minimizing assembly steps and contamination risks.

4. Drug Delivery Systems: Precision Control of Dosage and Release

Insulin pens, inhalers, and microneedle patches demand extreme dosage accuracy. Injection molding reduces drug residue through ultra-smooth mold surfaces (Ra≤0.05μm) and ensures long-term stability with low-moisture-absorption materials like LCP.

III. Three Core Advantages of Medical Injection Molding

The medical industry’s pursuit of cost, precision, and efficiency makes injection molding the preferred manufacturing solution:

1. Cost-Effectiveness: The “King of Value” in Mass Production

- Low mold amortization cost: A medical-grade mold can last over 500,000 cycles, with per-unit costs dropping exponentially as production volume increases.

- High material utilization: Injection molding wastes <5% of material, compared to ~30% in CNC machining.

- Automation-driven cost reduction: Paired with robotic arms and vision inspection systems, it enables 24/7 unmanned production, cutting labor costs by 70%.

2. Precision Guarantee: Millimeter Tolerances, Micron-Level Control

- Mold precision determines product precision: Techniques like five-axis machining and EDM achieve mold cavity tolerances within ±0.002mm.

- Full-process monitoring: Sensors track every parameter—from resin drying and injection pressure to cooling time—ensuring >99.9% consistency across molds.

- Post-processing refinement: Electropolishing reduces surface roughness to Ra0.02μm for critical contact areas, meeting aseptic operation requirements.

3. Flexibility and Scalability: From Prototyping to High-Volume Production

- Rapid mold changeovers: Hot runner systems and modular mold designs cut changeover times from 4 hours to 30 minutes, supporting multi-variety, low-volume production.

- Broad material compatibility: Injection machines adapt to over 200 medical plastics, from standard PP to high-performance PEEK.

- High design freedom: Techniques like gas-assisted injection molding and thin-wall molding produce lightweight parts (wall thickness <0.5mm) without sacrificing structural integrity.

Conclusion: Injection Molding—The “Underlying Engine” of Medical Innovation

While 3D printing explores the frontiers of personalized medicine, injection molding has spent decades building the “standardized foundation” of medical manufacturing. From cost to precision, from efficiency to compliance, this seemingly traditional process continues to drive the industry toward safer, more accessible healthcare solutions. For medical professionals, mastering injection molding’s advantages may be the key to unlocking next-generation product innovation.