In the precision-driven world of injection molding, parting surface design serves as the “nervous center” of mold structure. It not only determines the success of plastic part ejection but also directly impacts product quality, mold lifespan, and production efficiency. This article systematically dissects the core logic of parting surface design, empowering you to master this critical technology.

I. The Essence and Common Types of Parting Surfaces

Parting surfaces act as the “separable interfaces” within mold cavities, fulfilling three core requirements: smooth ejection of plastic parts and condensate, precise installation of inserts, and sealed molding of molten plastic. When mold manufacturing precision is insufficient or clamping force is inadequate, the melt may extrude through parting surfaces, forming flash that leaves permanent marks even after trimming.

Based on geometric characteristics, parting surfaces fall into four categories:

- Horizontal Parting Surfaces: Basic planar structures for simple parts

- Stepped Parting Surfaces: Multi-level designs for complex ejection

- Tapered Parting Surfaces: Angled solutions for side-core pulling

- Curved Parting Surfaces: Freeform surfaces for irregular geometries

Modern mold design is breaking free from traditional planar constraints, with composite applications of curved and stepped surfaces becoming standard in high-end molds. For instance, 3D curved parting technology in automotive lens molds reduces ejection resistance by over 40%.

II. Six Golden Rules for Parting Surface Design

Rule 1: Ejection-Oriented Prioritization

Ideal designs ensure parts automatically remain on the moving mold side during opening. A typical solution positions the main core on the moving mold, causing the shrunk part to wrap around it while the cavity stays on the fixed side. For parts with inserts, “cavity-following moving mold” designs place complex structures on the moving cavity side for integrated ejection. A home appliance manufacturer improved ejection success rates from 82% to 99% through such optimization.

Rule 2: Structural Simplification

When parts feature special geometries, parting surfaces should be reconstructed to simplify machining. A medical catheter connector mold reduced costs by ¥32,000 per set by changing from planar to 15° tapered parting, converting deep cavities requiring EDM into simple milled planes.

Rule 3: Integrated Venting Systems

Venting slots should be positioned at melt flow terminals, forming “venting corridors” with parting surfaces. A precision electronic component mold reduced air trap defects from 18% to 0.5% by optimizing vent slot placement (3mm further from gates). For ABS materials, optimal venting requires a 0.02mm slot depth.

Rule 4: Dual-Dimension Precision Control

Parting surfaces must satisfy both concentricity and dimensional accuracy. In an axial component mold, positioning the parting surface at the mid-plane of axial tolerance zones achieved 0.01mm concentricity, triple the precision of conventional designs.

Rule 5: Appearance Seamlessness

Parting lines should avoid product front faces, with “invisible parting” techniques essential for transparent parts. An automotive lamp cover mold achieved complete parting line concealment by relocating it to edge decorative ribs, boosting pass rates by 25 percentage points.

Rule 6: Equipment Efficiency Maximization

Avoiding long-distance core pulling is key to efficiency. A communications equipment housing mold reduced opening stroke by 30% and equipment utilization by 18% through a “slanted ejector + slider” compound mechanism, cutting core pulling distance from 120mm to 45mm.

III. Future Trends: Intelligent Parting Design

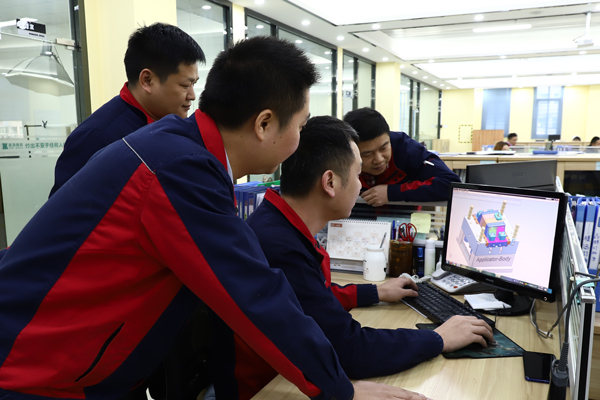

With AI integration, parting surface design is entering a smart era. A mold enterprise’s AI system now generates 3-5 parting solutions from 3D part models, predicting ejection forces and deformations via finite element analysis, cutting design cycles from 72 to 8 hours.

Conclusion: Parting surface design represents the “art of equilibrium” for mold engineers, requiring optimization across functionality, cost, and efficiency. Mastering these six rules not only enhances mold quality but also builds technological barriers in competitive markets. What challenges have you encountered in parting surface design? Share your experiences in the comments to explore solutions together!