Necessity of precision mold parts inspection :

In the production process of precision mold parts , due to changes in accuracy, quality, India, appearance, etc., the final product needs to be consistent with the initial requirements of the customer to avoid changes in the mold during the work process, so precision mold parts inspection must be carried out to ensure the final The mold produced meets the requirements

In what aspects does the precision mold parts inspection carry out inspection?

Mainly in the following four aspects:

1. Measure the angle and taper

2. Measure roundness and axiality

3. Measure parallelism and perpendicularity

4. Detect the cavity of the mold

=

=

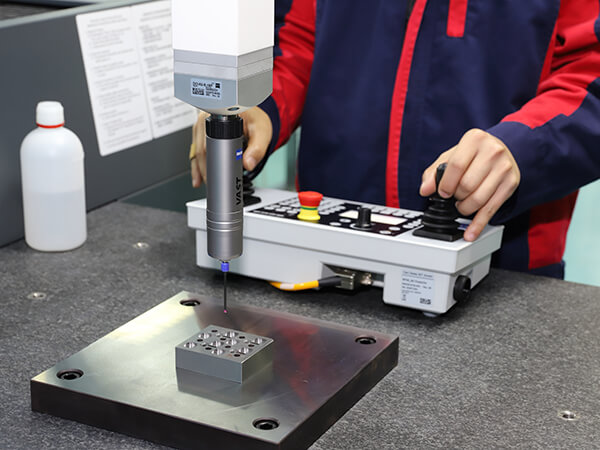

Yize Mould established a quality inspection room to pass electrode inspection and three-coordinate inspection, Projector inspection,Visual inspection, Tool microscope inspection and other inspection tools for the whole process quality inspection of raw materials, semi-finished products, finished products, injection molded products, reports, packaging and other processes,Material, strictly implement the ISO9001 quality management system.